Patterns of Wheelchair Frame Impact Response in Frontal Sled Tests

Julia E. Samorezov, Miriam A. Manary, Monika M. Skowronska, Gina E. Bertocci*, and Lawrence W. Schneider

University of Michigan Transportation Research Institute

*University of Louisville

ABSTRACT

The frame response of wheelchairs used as seats in motor vehicles was characterized under impact loading conditions using data from 575 frontal sled tests. Wheelchairs (WC) were power, manual, or stroller types and the seating systems were described as fabric or planar. Loading mechanisms that caused damage were identified and the effect of seating system type considered. The most frequent types of WC frame responses were failure or deformation of the securement points or the adjacent frame, structures supporting the seat, front casters, footrests, tilt/recline mechanisms, and seatback canes. WC rotation showed little relationship with frame response. The findings will aid in the design of a reusable surrogate wheelchair seating system (SWCSS) for crash testing of wheelchair base frames.

Keywords:

wheelchair frame failures, crashworthiness, crash testing, wheelchair transportation safety

BACKGROUND

Sections 19 and 20 of ANSI/RESNA, Wheelchairs Used as Seats in Motor Vehicles (WC19), and Seating Devices for Use in Motor Vehicles (WC20) have improved protection of wheelchair-seated occupants in motor-vehicle crashes by establishing design and performance criteria for wheelchair crashworthiness (1,2). WC19 defines a procedure for crash testing and evaluation criteria for forward-facing wheelchairs. However, only an entire wheelchair, consisting of a base/frame and seating system, can be tested to WC19. WC20 extends this standard by allowing independent testing of a seating system using a surrogate wheelchair base (SWCB). Independent testing of seating systems and base frames is important because an individual’s needs may require a unique hardware combination and it is not practical to crash test every possible seat/frame pairing. However, there is currently no way to independently test a wheelchair base or frame. The development of a SWCSS would be a key step towards a standard for independent testing of wheelchair frames. Because the SWCSS should load a wheelchair base much like worst-case conditions with commercial seating systems, it is necessary to study how commercial wheelchair bases respond to crash loads.

OBJECTIVES

The study describes wheelchair frame impact responses in frontal sled tests of forward-facing wheelchairs. The results can guide design of a SWCSS for independent testing of wheelchair bases.

METHODS

Data from frontal-impact tests of forward-facing adult (N=412) and pediatric (N=163) wheelchairs conducted between January 1998 and May 2007 were reviewed. The crash tests were run per WC19 (48-kph, 20-g) on the UMTRI impact sled and constitute a wide sample of current wheelchairs, including models from almost every US manufacturer. Included in this analysis were 165 manual wheelchairs (28.7%), 182 power wheelchairs (31.7%), and 228 strollers (39.7%). For each test, wheelchair size/type and mass, anthropomorphic test device (ATD, a.k.a. crash test dummy) size, occupant restraint type, ATD and WC peak excursions, peak loads in the tiedowns and occupant restraint belts, and test outcomes in accordance with WC19 were documented. Pre- and post-test photographs, along with descriptions from the test reports, were used to identify the location and nature of frame damage. Test videos were reviewed to determine loading mechanisms and wheelchair and ATD kinematics. The WC frame was defined as all WC components except the seat, seatback, and the seat/seatback attachment hardware.

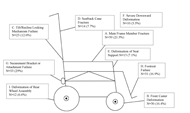

Damage to the wheelchair frame was grouped into nine categories described in Figure 1. Categories A-F were considered seating-dependent outcomes because seating type likely influences how loads are distributed to these components. Categories G-I were classified as seating-independent outcomes to reflect that the seating system type was unlikely to change the results. Right side-view wheelchair rotation was categorized as either clockwise rotation (forward), counterclockwise rotation (rearward), no rotation, and not applicable (used if securement point failed or WC collapsed).

| Category | Description of Outcome | Example Photograph |

|---|---|---|

| A. Main Frame Fracture | fracture of the seatrails, any other lateral and longitudinal frame members, or the X-member in folding manual wheelchairs. | |

| B. Front caster deformation | downward and rearward bending, and sometimes fracture, of the vertical frame members to which the front casters are attached | |

| C. Failure of the tilt or recline locking mechanism | slipping of the mechanism resulted in seatback rotating around the seatback-seat junction (only if mechanism was mechanical, not battery powered) | |

| D. Seatback cane fracture | complete or partial fracture of one or both seatback canes. | |

| E. Deformation or failure of seat support member | severe deformation of the components connecting the seat to the wheelchair base, sometimes leading to complete separation of the seat frame from the base | |

| F. Severe downward deformation | downward and outward splay of the wheels - the front and rear wheels spread out but no fracture occurred | |

| G. Securement point / member supporting securement point failure | fracture or detachment of one or both rear securement brackets, or of the frame member to which the securement brackets attach | |

| H. Footrest failure | fracture or detachment of one or both footrests or footplates | |

| I. Damage to the rear wheel assembly | fracture of the rear wheels or wheel hubs, or of the frame members to which rear casters attach |

RESULTS

Table 1 and Figure 2 show the frequency of frame outcomes. The wheelchair experienced fracture or deformation of frame components in 183 tests (31.8%). Of these, 160 (87.4%) the deformation was significant enough to constitute failure according to WC19. Many wheelchairs had multiple deformed components and so were counted in more than one category.

The most common outcome was deformation/fracture of the rear securement brackets or the adjacent frame (29%), which occurred primarily on power wheelchairs. Not coincidentally these are the heaviest wheelchairs with an average mass of 116.9 kg (+/- 27.3SD), compared with 23.4 kg (+/- 6.2 SD) for manual wheelchairs and 20.7 kg (+/- 6.0 SD) for strollers. Other failures that occurred almost exclusively on power wheelchairs included deformation of the seat support member or of the rear wheel assembly. Power wheelchair frames with damage in these three categories also rotated most frequently. Of all power wheelchairs that rotated, 8.0% experienced failures of securement bracket or attachment, 8.1% deformation of the seat span support and 8.1% failures of the rear wheel assembly.

Front caster deformation (16.4%) and footrest failures (16.9%) were also common. In 43% of the tests, moderate front caster deformation was noted but did not cause failure as defined by WC19. Footrest failures ranged from a detached footplate to tubing fracture to complete detachment. Contact with the sled platform or bolster that occurred in 14.8% of tests with footrest failure may have contributed to failure, but ATD loading of the footrests was considered to be the primary cause.

The most common of the seating-dependent outcomes was a fracture in the main frame (21.3%) and most of these fractures occurred in seat rails or members supporting the seat. Failure of a tilt or tilt-and-recline locking mechanism was also common, particularly for strollers, comprising 12.6% of all frame failures. Fracture of the seatback canes (7.7% of all frame damage) occurred at similar frequencies in all wheelchair types and was caused either by the force of the forward rotation of the seatback while the base of the wheelchair was held stationary, or, more commonly, by ATD rebound loading. Severe downward deformation of the main wheelchair frame (5.5% of all frame damage) occurred mostly in strollers.

Seating-dependent loading patterns that caused fracture or deformation of wheelchair components are shown in Table 2. Some wheelchair frames exhibited deformation caused by more than one loading type, and thus were counted in more than one category. The loading type is unknown for some wheelchairs, but pre- and post-test photos indicate that the seating-dependent damage of the wheelchair frame occurred. The majority of seating-dependent damage occurred because of the initial forward/downward loading through the seat by the ATD. However, rebound loading accounted for 38.7% of such damage. Rarely, the shear force from the rear tiedowns securing part of the wheelchair while the seat frame and seating system moved relative to the base caused frame damage. Most frame outcomes associated with forward/downward loading were in the categories of main frame fracture, failure of the tilt/recline mechanism, failure of seatpan support, and severe downward deformation . Frame outcomes associated with rebound loading included mostly the categories of main frame fracture, seatback cane fracture, and failure of the tilt/recline mechanism.

| Loading type | # of wheelchairs |

|---|---|

Forward/downward loading on impact |

63 |

Loading from ATD rebound |

36 |

Shear force caused by tiedown loading |

8 |

Other / Unknown |

12 |

Wheelchairs with a fabric seats exhibited frame damage more often than wheelchairs with a planar seats, especially under rebound loading, and suggests that a fabric seat provides worst-case loading. Table 3 compares the occurrence of seating-dependent frame outcomes in wheelchairs with planar and fabric seats. Power wheelchairs rotated most frequently of all WC types (50.3 %), manual wheelchairs rotated least frequently (14 %) and strollers where in between with a 24.2 % frequency of rotation (Table 4). Wheelchairs with a fabric seats were most likely to rotate: 42.6% of these wheelchairs experienced rotation, as compared to approximately 30% of wheelchairs with planar/customized seats. Power wheelchairs experienced more rotation in all seat type categories than any other wheelchair type. Approximately 50% of power wheelchairs experienced rotation; only power wheelchairs with fabric seat pans experienced less than 50% rotation (33.3%). Manual wheelchairs rotated least often, with strollers in the middle. However, strollers with fabric seat pans rotated in 86.7% of tests, and all of these rotations were clockwise. Overall, seatback type had no discernable effect on wheelchair rotation. Out of all WC that experienced at least one failure mode 53.0% power, 34.3% stroller and 29.3% of manual WC experienced both rotation and failure.

|

Seating-dependent Frame Damage (categories A-F) |

Seating-dependent Frame Damage due to Forward/ Downward Loading | Seating-dependent Frame Damage due to Rebound Loading |

|---|---|---|---|

| Fabric Seat (n = 113) |

26.5% |

13.3% |

10.6% |

| Planar Seat (n = 463) |

17.9% |

10.2% |

5.2% |

|

|

|

Clockwise |

Counterclockwise |

Total |

|---|---|---|---|---|---|

|

|

|

rotation (%) |

rotation (%) |

rotation (%) |

Manual |

Seat |

planar |

10.9 |

1.4 |

12.3 |

fabric |

16.7 |

4.2 |

20.8 |

||

Seat back |

planar |

3.3 |

1.1 |

4.3 |

|

fabric |

19.4 |

1.6 |

21 |

||

Power |

Seat |

planar |

17.1 |

34.8 |

51.9 |

fabric |

0 |

33.3 |

33.3 |

||

Seat back |

planar |

12.4 |

43.8 |

56.2 |

|

fabric |

20.3 |

28.4 |

48.6 |

||

Stroller |

Seat |

planar |

21.5 |

5.1 |

26.6 |

fabric |

86.7 |

0 |

86.7 |

||

Seat back |

planar |

31.5 |

9 |

40.4 |

|

fabric |

24.3 |

0 |

24.3 |

||

Totals |

Seat |

planar |

16.7 |

14.3 |

31.1 |

fabric |

31.5 |

11.1 |

42.6 |

||

Seat back |

planar |

15.6 |

17.8 |

33.3 |

|

fabric |

21.4 |

10.5 |

31.9 |

DISCUSSION

The results of this wheelchair frame response analysis have several implications for surrogate seating system design. The SWCSS must: 1) transmit maximal loads to the seatback canes, seatrails, and frame while not strengthening any structural components, 2) allow for testing of frame tilt and recline mechanisms, 3) maximize forward/downward loading through the seat, and 4) maximize rebound loading on the seatback. Because fabric seating may introduce worst case loading of the wheelchair frame, but most specialized seating systems will be planar or customized, two tests may be necessary to test a wheelchair base. The first of these would be with a fabric seat to maximize both rebound and inward frame loading, the second with a planar seat to maximize downward loading.

Wheelchair rotation was shown to have no clear effect on frame outcome and shows no clear relationship with a specific failure mode. For the two outcomes that were associated with a higher frequency of rotation (front caster deformation and deformation of rear wheel assembly), examination of the video data shows that rotation was a result, not a cause, of the damage. Since power wheelchairs rotated most frequently and half (53.0%) of power WC with at least one failure mode also experienced rotation.

Design changes could minimize rotation and improve user comfort and safety.

Because the loading mechanisms that caused seating-independent damage were largely unaffected by the wheelchair seating system design, these are less useful to the SWCSS development process. However, studying these frame response patterns yields some insight into designing WC19 complaint wheelchairs. The most common of the seating-independent outcomes, securement point failure, can easily be addressed by strengthening securement point brackets and their attachment hardware. Others, such as footrest failure and front caster deformation also highlight issues of interest to WC manufacturers.

LIMITATIONS

The retrospective data was limited to that which could be gathered from test reports, photographs, and videos. The wheelchairs that were tested were not directly examined. In particular, seating system type was sometimes determined from photographs alone, which could introduce classification errors.

CONCLUSIONS

A review of 575 WC19 frontal-impact sled tests of commercial wheelchairs revealed clear patterns in wheelchair frame response. Wheelchair frame outcomes were divided into seating-dependent and seating-independent. The most common frame outcome was damage to a rear securement bracket, occurring in 29% of all tests with frame damage. The most common seating-dependent outcome was the fracture of a main-frame member, which occurred in 21.3% of all tests with frame damage. Forward and downward loading through the wheelchair seat and rebound loading of the ATD against the seatback were found to be the primary loading mechanisms. Wheelchairs with fabric seats experienced frame damage more often than wheelchairs with planar seats, especially damage caused by rebound loading (10.6% of wheelchairs with a fabric seat failed in this way, compared to only 5.2% of wheelchairs with a planar seat) and may provide worst case loading of the wheelchair frame. A SWCSS is necessary to test wheelchair bases or frames independent of seats, and should approximate worst-case loading by a commercial seating system. The SWCSS must not strengthen the frame or divert loading from any structural components of the wheelchair, and must maximize both rebound and forward/downward loading.

ACKNOWLEDGMENTS

The RERC on Wheelchair Transportation Safety is funded by the National Institute on Disability and Rehabilitation Research (NIDRR), Department of Education, Washington, D.C., Grant # H133E060064. The opinions expressed herein are those of the authors and do not necessarily reflect NIDRR opinions.

REFERENCES

- ANSI/RESNA Subcommittee on Wheelchairs and Transportation (2000). ANSI/RESNA WC/Vol.1, Section 19:Wheelchair Used as Seat in Motor Vehicles.

- ANSI/RESNA Subcommittee on Wheelchairs and Transportation (2008). ANSI/RESNA WC/Vol.4, Section 20: Seating Systems Used in Motor Vehicles.

Author contact information: Miriam Manary, UMTRI, mmanary@umich.edu.